Stability Reliability Quality

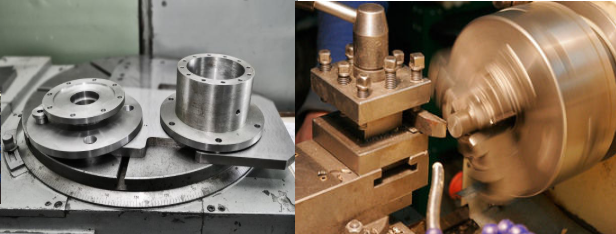

Metal machining

Coordinate and boring work. Overall dimensions of machined parts: 1100x700x630 mm.

The main types of work (boring, drilling, marking) performed on coordinate boring machines is performed with an accuracy of 0.01 mm.

Turning works of any complexity

Production of shafts up to 2500 mm long and up to 300 mm in diameter, cutting of 2,3,4 ground worms

(DIP-300 machines with an extended bed, 16K20, 1K62).

Milling work

On horizontal and vertical universal machines, the maximum size of the table is 1400×400 mm.

Slotting of the slots and keyways with a length of up to 200 mm and a width of the groove up to 30 mm.

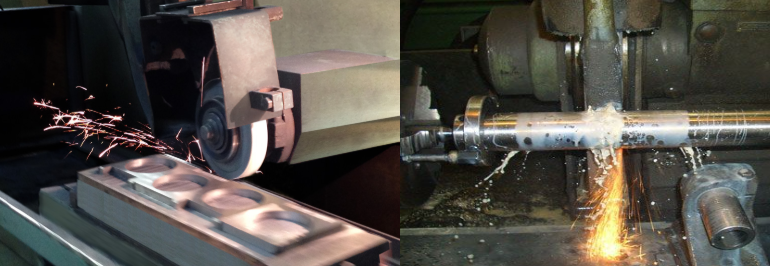

Circular grinding work

(shaft length 600 mm, Ø 300 mm)

Surface grinding work

(size of magnetic plate 200×400 mm)

Cutting spur, helical and worm gears to module 5 and a diameter of 450 mm inclusive.

Create by cybergroup.com.ua

.svg)