Boiler Repair Department

The Boiler Department of the company specializes in performing complex technical tasks in the field of power engineering machinery. Thanks to many years of experience and the high qualifications of our personnel, we ensure reliable and efficient execution of work of any complexity.

MAIN TYPES OF WORK PERFORMED BY THE BOILER DEPARTMENT:

- Installation, repair, and reconstruction of boilers of small and large capacity.

- Reconstruction and modernization of steam boilers aimed at increasing steam production and switching to a different type of fuel.

- Conversion of steam boilers to hot water operation mode.

- Reconstruction and repair of pressure vessels.

- Manufacturing of boiler elements, pipelines, and vessels.

- Performing special rigging operations.

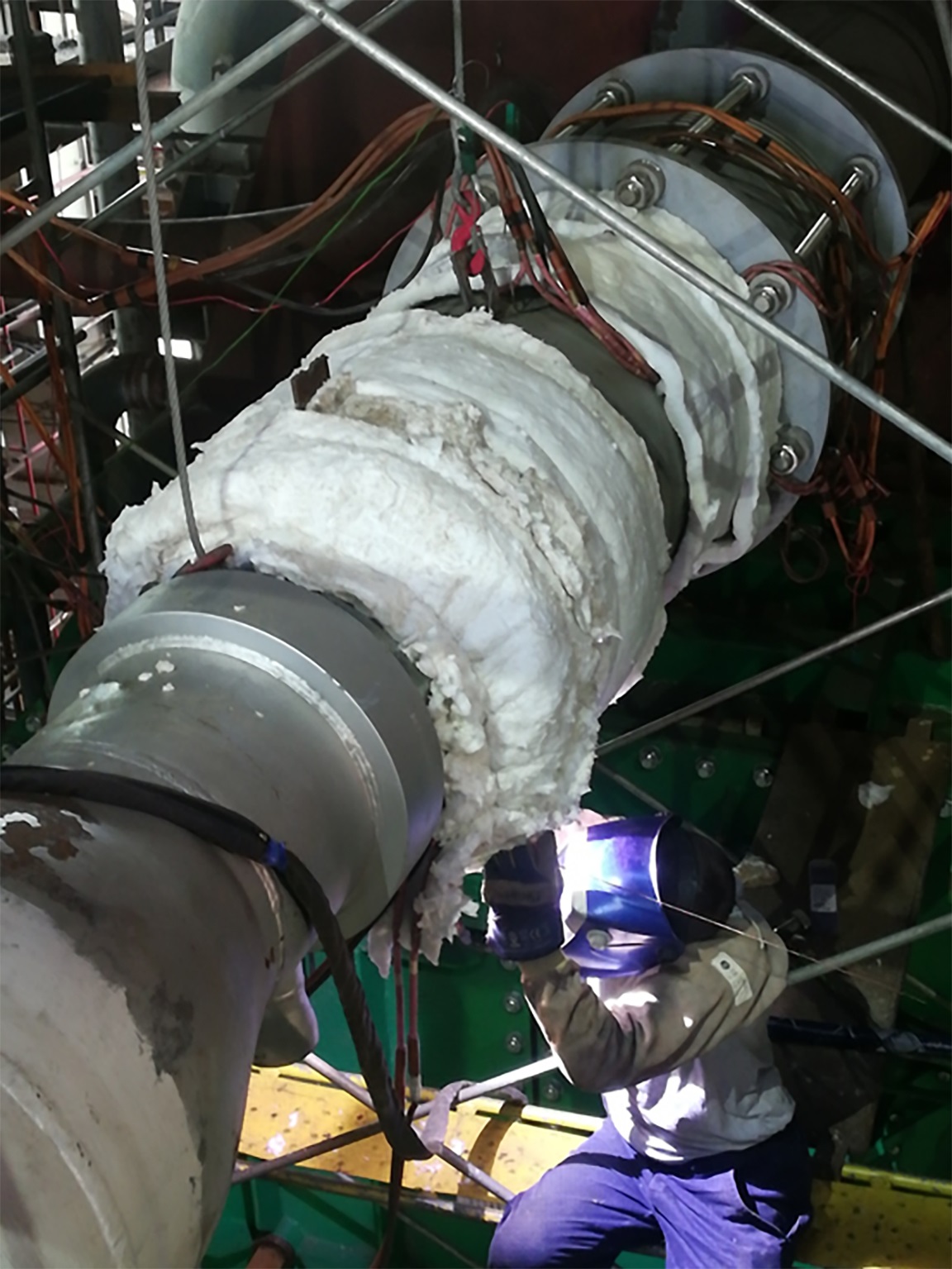

- Repair and installation of boiler equipment, flue ducts, and pipelines.

All works are performed in accordance with current regulatory and technical documents, using modern technologies and equipment.

Implementation of individual engineering solutions, quality control at all stages of the production process, and strict adherence to deadlines are the key principles of the Boiler Department’s activity in our company.

In 2022, repair work was carried out on the flue ducts of boiler No. 1 at the Kryvyi Rih TPP of DTEK.

![[:uk]Фото Турбіна[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/Фото-Турбіна-rc2se1usdyhej3i933pstb19k9s84kac2dur0s3wkg.jpg)

![[:uk]2 photo_2025-05-15_18-06-36[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/2-photo_2025-05-15_18-06-36-rc2sfvnhoczh3suoew5onufj58rx3djjnfiqm5ecgw.jpg)

![[:uk]1.[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/1-4-rc2sfbwvou8gbzncm5mipheuo5h7lqd6kptjjc7m3k.jpg)

![[:uk]Котли Изображение 076[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/Котли-Изображение-076-scaled-rc2sietu3agadz68mhkhvpf8rmaiu0libysu5zn5pc.jpg)

![[:uk]3.[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/3-3-rc2sgaowppk29k8tz2nprqmwnepsij791hyiaks1pc.jpg)

![[:uk]2.[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/2-3-rc2sfvnhoczh3suoew5onufj58rx3djjnfiqm5ecgw.jpg)

![[:uk]Котли Изображение 400[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/Котли-Изображение-400-rc2sigpigyiv173ibidr0oy5ye199esz083t4jkdcw.jpg)

![[:uk]Котли Изображение 412[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/Котли-Изображение-412-rc2sigpigyiv173ibidr0oy5ye199esz083t4jkdcw.jpg)