Turbine Department

MAIN TYPES OF WORK PERFORMED BY THE TURBINE DEPARTMENT:

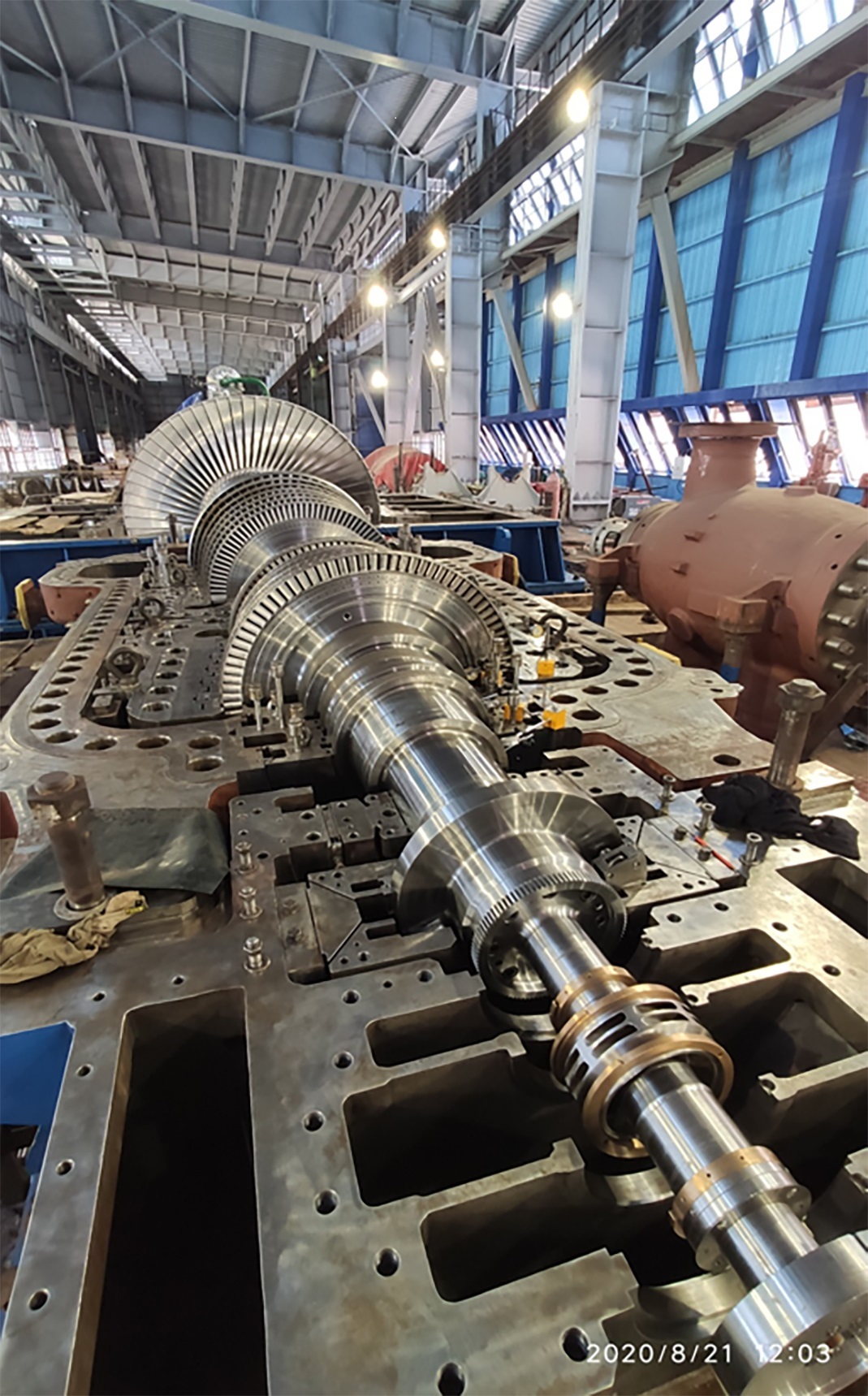

- installation, repair, modernization, reconstruction, and commissioning of turbo units and their auxiliary equipment;

- standard and specialized repairs of all types of steam, hydraulic, drive, and gas turbo units, with a warranty for the completed work;

- overhaul, testing, and tuning of automatic control and steam distribution systems of various turbine types;

- supply of equipment and spare parts for turbine equipment;

- overhaul and adjustment of all types of pumps, manufacturing and repair of heat exchangers and other equipment either on-site or at the company’s production base.

- replacement of working blades of turbine rotors from 6 MW to 1000 MW with subsequent machining and rotor balancing;

- analysis and elimination of excessive vibration in turbo units and all rotating mechanisms, dynamic balancing of rotors in their own bearings, vibration adjustment of turbogenerators.

![[:uk]изображение_viber_2023-07-10_16-35-38-390[:] [:uk]изображение_viber_2023-07-10_16-35-38-390[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/изображение_viber_2023-07-10_16-35-38-390-rc2si88zzb0unwa3ryy72jleeyazjo1h1tta0dg314.jpg)

Turbine repair is one of the core areas of activity for KHARKIVENERGOREMONT-HOLDING. Between 2021 and 2025 alone, the department’s specialists have carried out and continue to perform various levels of repair work on more than 10 turbine units ranging in capacity from 25 MW to 1000 MW at multiple power plants (Khmelnitskyi NPP, Zmiivska TPP, Trypilska TPP, Burshtynska TPP, Cherkaska CHP, Kherson CHP, Bila Tserkva CHP, the CHP of “KAMET-STEEL” metallurgical plant, and others).

In 2020–2021, a new DST-S20-6CD2R turbine with a capacity of 260 MW, manufactured by Doosan Škoda Power, was installed at the “Lidio Ramón Pérez” TPP in the Republic of Cuba.

In 2017, the low-pressure backup rotor of the K-200-130 LMZ turbine at the Estonian Power Plant was repaired, including transportation of the rotor to Ukraine and back to Estonia.

In 2016–2017, as part of the overhaul of Unit No. 5 at the “Ghorashal” TPP in the People’s Republic of Bangladesh, a major repair of the K-210-130 LMZ turbine and its auxiliary equipment was carried out. This was the first such overhaul since the unit’s commissioning in 1989. After the repair, the turbine confidently reached its full rated capacity of 210 MW.

We have also completed a number of complex projects, including the repair of K-500-240-2 turbines at the Ekibastuz GRES in Kazakhstan, the overhaul of a K-300-240 turbine at the “Ramin” TPP in Iran, the major repair of a Chinese N 210-130 Harbin turbine at the “Jamshoro” TPP in Pakistan, as well as the reconstruction and modernization of turbine units No. 1 and No. 2 at the “Obra” TPP in India, and the repair of K-300-240 and VK-100 turbines in Vietnam.

In addition, we maintain close working relationships with the subsidiary of JSC “Ukrainian Energy Machines” — the “Turboatom” plant, the Poltava Turbomachinery Plant, and other manufacturers and suppliers of turbine spare parts, which enables us to provide Customers with comprehensive repair services including the supply of all necessary spare parts.

![[:uk]1[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/1-3-rc2sfaz1i0760doprn7w4zne2rlue19g8l6222909s.jpg)

![[:uk]1изображение_viber_2023-07-10_16-27-02-484[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/1изображение_viber_2023-07-10_16-27-02-484-1-rc2sfm93s0mlvp8bxs3eywsx7e28yei8a4zvtdsa74.jpg)

![[:uk]5изображение_viber_2023-07-10_16-27-03-511 (1)[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/5изображение_viber_2023-07-10_16-27-03-511-1-1-rc2sgnunde22s3ppu8chqnbcyswxianhrb3b0g8ja8.jpg)

![[:uk]2[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/2-2-rc2sfupnhiy6s6w1kdr23co2juwjvoftbav94vfqn4.jpg)

![[:uk]6[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/6-3-rc2sgqo5xw5xqxlmdrkdg4lqqyj15dyorp1rga4crk.jpg)

![[:uk]2изображение_viber_2023-07-10_16-27-02-964[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/2изображение_viber_2023-07-10_16-27-02-964-1-rc2sg6xjydewz4eal117hrl29v8bnqsbozckdgxme8.jpg)

![[:uk]5[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/5-4-rc2sglyyzpzi4vsg57j8lnsfs1672wg131sc1wbbmo.jpg)

![[:uk]8[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/8-1-rc2sgufip8b31dg5rt6vq3nl4i0i06dm47npddys2o.jpg)

![[:uk]изображение_viber_2023-07-10_16-27-03-686[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/изображение_viber_2023-07-10_16-27-03-686-1-rc2si2lxmfzk71nzluachai91lyr1y8zyabixe59y8.jpg)

![[:uk]изображение_viber_2023-07-10_16-27-03-908[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/изображение_viber_2023-07-10_16-27-03-908-1-rc2si3jrta0uinmmgcoz1s9pmzu49ncqaez0eo3vs0.jpg)

![[:uk]изображение_viber_2023-07-10_16-30-14-409[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/изображение_viber_2023-07-10_16-30-14-409-1-rc2si4hm0424u9l9av3lma168dphhcggmjmhvy2hls.jpg)

![[:uk]изображение_viber_2023-07-10_16-33-02-372[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/изображение_viber_2023-07-10_16-33-02-372-1-rc2si6dads4phhiizvwur9k3f5g7wqnxasxguhzp9c.jpg)

![[:uk]Фото стр (3) турбіна[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/Фото-стр-3-турбіна-rc2sdy3fmmc98nnpp23ajbzf6qar9rvepv8t3o9h9c.jpg)

![[:uk]Фото стр (2) турбіна[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/Фото-стр-2-турбіна-rc2sdx5lfsayx1p2ujonyu7ylcfe22rodqlbmeavfk.jpg)

![[:uk]Фото Турбіна[:]](https://khaer.com.ua/wp-content/uploads/elementor/thumbs/Фото-Турбіна-rc2se1usdyhej3i933pstb19k9s84kac2dur0s3wkg.jpg)