Департамент з ремонту котлів

ОСНОВНІ ВИДИ РОБІТ КОТЕЛЬНОГО ДЕПАРТАМЕНТУ:

- Монтаж, ремонт і реконструкція котлів малої і великої потужності.

- Реконструкція і модернізація парових котлів з метою збільшення виробництва пари та переходу на інший вид палива.

- Переведення парових котлів на водогрійний режим роботи.

- Реконструкція і ремонт посудин, що працюють під тиском.

- Виготовлення елементів котлів, трубопроводів, посудин.

- Виконання спеціальних такелажних робіт.

- Ремонт та монтаж котельного обладнання, газоходів, трубопроводів.

У 2012 р. котельні бригади нашої компанії виконали демонтаж старого і монтаж нового котельного обладнання з реконструкціею топкових систем, монтаж двох димових труб ТЕЦ рудника Баренцбург, архіпелаг Шпіцберген, Норвегія. Роботи виконувались у вкрай важких умовах крайньої півночі.

Котельний склад департаменту також виконав капітальні ремонти котлів №7 і №9 Шосткинсько’і ТЕЦ з виготовленням і заміною ширмових пароперегрівачів і економайзерів котлоагрегатів БКЗ-160-100ГМ. Виготовлення ширмових пароперегрівачів і економайзерів виконувалось на власній виробничій базі нашої компанії.

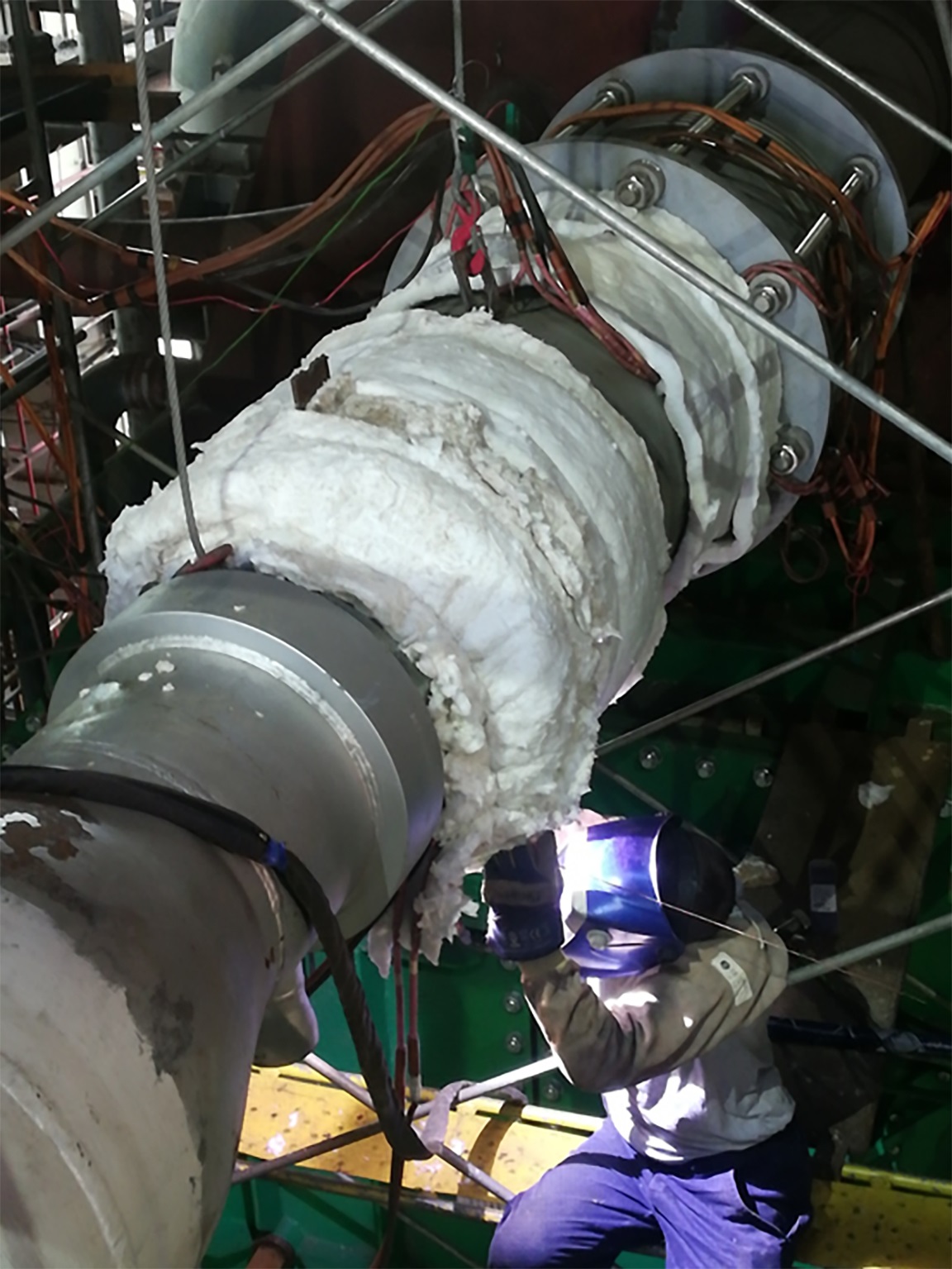

У 2020-2021 роках був виконаний монтаж 80 тон трубопроводів від котла до турбіни на енергоблоці №1 потужністю 260 МВт на ТЕС «ЛІДІО РАМОН ПЕРЕС» у Республіці Куба.

У 2022 році був виконаний ремонт газоходів котла ст. №1 Криворізької ТЕС ДТЕК.